At the Hassmoor Tractor Pull fans and competitors alike took a very close look at the Green Monster Tractor. The Allison engine on the front of the tractor was equipped with an electronic motor management system.

The Green Monster team is not the first team to use a system like that on a pulling tractor, but it probably was the first team to

A) use only one nozzle per cylinder

B) hammer down a Full Pull and leading distance in the Pull Off at the very first time out and

C) cause a lot of discussions after hammering down another, very impressive Full Pull in the 2.5t class, that made the competition raise it's eyebrows.

To sum it up: The conversion was an instant success, that was not even expected by the team themselves.

Since I was deeply involved into this conversion and it caused like 3 weeks of downtime on this website, I want to give you a little "behind the scenes" look of how it works.

After a not too successful test run with a new supercharger at the Euro Cup Finals at Bettborn we figured, we have problems getting the characteristic of that supercharger into our mechanical fuel system.

Something had to be found that could get this mechanical change to work well - and in a very short time.

Since EFI (Electronic Fuel Injection) Systems are allowed in ETPC competition since 2006 and two Teams in Australia and England had already managed to run EFI on Rover Meteor V12s I started some research on avaliable systems.

I found a lot of fuel management systems, a few even capable of V12 engines - but had a problem finding anything that could deliver the amount of fuel it takes to power a V12 Allison.

More or less by accident I ran into a supplier of injectors big enough for our needs.

But they do not only build injectors, they race with centrifugal supercharged as well as twin turbocharged engines and heavily support a Motor Management System, that is big enough, rugged enough and fast enough to handle the needs of a V12 Allison engine in Tractor Pulling trim - and then some.

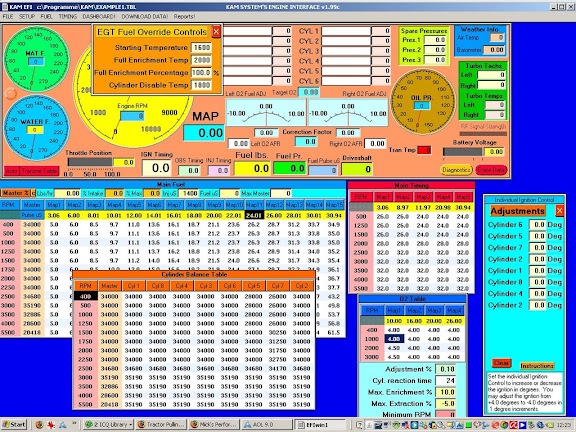

The system can handle up to 12 cylinders with extreme boost pressures with fuel and distributerless ignition and comes with a really fast and very accurate Datalogger. It also has automatic features where they are needed and can be manually programmed to do what it should do where and when you want it. We first were a little concerned about costumer support, but the guys went way beyond expectation to help us get this thing to run by coming over to germany to help us install and set up the system into a pretty much "competetive and running" state, as it could be seen in Hassmoor.

We agreed on helping them on the EU market some and have for now taken over the distribution of this system in Europe. Which is the reason I can now show you details and don't need to hide information from the competition. If you want the same, we can now help you out and can also provide costumer service when it comes to spares and configuration help.

For the general set up we still need their help, but we can now shorten the time you have to hire these guys, based upon the experiences we have made by now.

From what I have figured so far, fine tuning the engine is childs play when you have a general understanding of things.

So basically what this system does, is to inject the right (or if choosen, the desired) amount of fuel for each individual cylinder, based upon the fuel map, Air / Fuel ratio and EGTs.

Up to 550 lbs/h per cylinder (880 lbs/h in the works) with one electric nozzle. It can also be staged ontop of a mechanical fuel system. So even if you need more than 550 lbs/h per cylinder, it's easy to add that extra amount with a normal CFI nozzle, that will be operated (turned on and off) by this system. The system will just add the CFI nozzles when needed, take that amount of fuel off it's calculation and keep control of it all. But you can also hook up to 32 electric nozzles if you wish to...

It also comes with a safety feature, that turns the fuel and igntion for an individual cylinder off, at a desired temperature. This is very handy

- when first setting up the system

- when you've became risky and tried to run it over the edge

- in case of mechanical failure

Under full load it will run in a "self operating" mode, where it monitors the EGTs of every individual cylinder and calculates the amount of fuel needed for the next combustion of each individual cylinder. Still you have control of how much it should add or extract away from your fuel map and at what temperatures you want it to operate this mode in.

Same goes for the A/F ratio - even though this one will be overridden by the EGT mode.

You can also adjust the amount of fuel for every cylinder by the fuel map. This also helps, when you loose an EGT sensor in a run and the system has no info to calcualte with. It will then run upon A/F ratio and the Fuel Map. So burning up stuff with this system is pretty hard to do...

The other neat thing is the ignition control. It will operate single coils (typical automotive spare parts, but also avaliable from MSD or other high performance companies by now) and you can layout you ignition table based upon rps and boost pressure.

Very nice to make it start well, retard timing under high boost levels or to use it as a very soft rev limiter, buy just pulling timing out when the engine gets near it's rev limit.

It also offers a "hard" rev limit as you can shut down fuel and ignition at the same time / rpm and just turn your cylinder into an air pump.

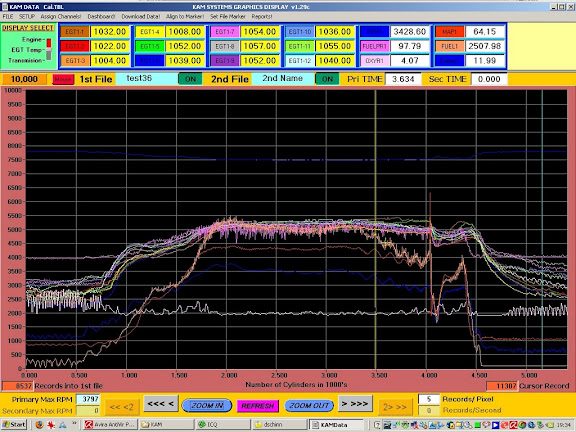

The data logger is also pretty neat.

1st of it's fast with a sample rate of 300 million per second. If you want to measure your combustion pressures at every half degree - just hook the right sensor and do it.

48 analog channels

8 digital channels

8 rpm channels

Cold Junction calibration of 12 thermo couplers (kinda neat.. just hook the sensor and it gives you correct data)

4 MB of built in Flash Memory

Since it's built "into the box" it also shows you stuff like the exact amount of fuel that was injected to every cylinder in the EGT override mode (pretty helpful when trying to get your fuel map closer to perfect).

And there is so much more that I have not yet discovered.

What I really like about it:

It generally works and it worked good instantly! No bull shitting from the suppliers end!

It makes the engine run good even if your fuel map is not 100% correct. If something is totally off, it shuts your cylinders in danger down and you can then see what you've done wrong, without melting stuff.

Once set up, you can also leave your hands off the system.

So there is no real need to parade around with a Lap Top in the pre pits to make a run down the track. If you wish you can of course check your datalogger info and adjust things that went wrong. In the very first run at Hassmoor we had two cylinders a little lean and they were shut down, so I gave them a little more fuel with two mouseclicks. But after that everything went smooth and the only result I got out of reading the data files in the track was, that I could have also downloaded them at the trailer and make changes there (it was like "Ok.. basically it works like hell - now where are the pulling specific advantages I can get into this system?).

Engine oil has very very little methanol in it after a weekend

Then engine got the nickname "Eco Bitch"... if it goes on like this, we'll have the system paid by the savings in methanol soon.

If you want, you can play "balls out" in the pits and impress the spectators with testing the function of every single injector and spark plug in the pits...

And after all, after seeing what it does for the price it costs, the investment was worth it. For us a datalogger that comes close to this one, an igntion system that can do what this one can do and a mechanical fuel injection would have cost pretty much the same. Of course we could keep our old fuel pump and we can now use the other stuff we took off on the other engines, but if it just saves us time in repair and helps us to perform a little better, after one season we should be financially better off with it than without it.

And finally: Changes made to the engines can now be gotten to run down the track a lot quicker than before. So we also should reduce "trial and error" time on the track and convert it into time we run in the competition.

EU requests for a complete system or the 550lbs/h injector nozzles can be send (or will be redirected) to greenmonsterteam@gmail.com

Requests from the USA or other countries to micksperformance@earthlink.net